Superfiltration Membrane Systems

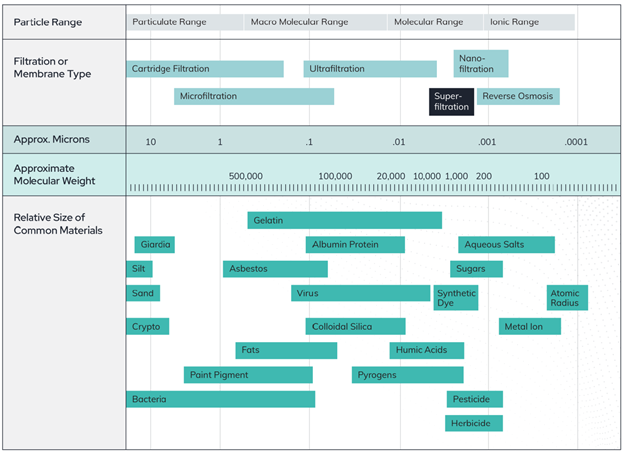

Utilize our advanced superfiltration membrane systems to reclaim valuable proteins, nutrients, and other products from waste streams. These superfiltration membranes represent a cutting-edge technology positioned between ultrafiltration and nanofiltration. They exhibit impressive nanofiltration-like organic rejection and ultrafiltration-like inorganic/salt rejection.

Our superfiltration membranes boast high hydrophilicity and employ patented chemistry, ensuring remarkable fouling resistance, even in streams traditionally deemed unsuitable for membrane separation.

Key Features

- Immune to irreversible organic fouling

- Reclaim proteins, nutrients, and more from waste streams

- Extend RO element lifespan and enable treatment in challenging scenarios

- Swiftly restore performance with short maintenance cleans using chlorine

- Featuring a nominal Molecular Weight Cut-Off (MWCO) of 1k Daltons, ensure precise filtration Proudly made in the USA, our Superfiltration Membrane Systems uphold the highest quality standards.

Enhanced Filtration Performance and Easy Maintenance

Experience the exceptional capabilities of our Superfiltration Membrane Systems in maintaining high flux rates, even in the presence of fats, oils, and proteins, while effectively rejecting over 99% of molecules with a molecular weight greater than 1kDa.

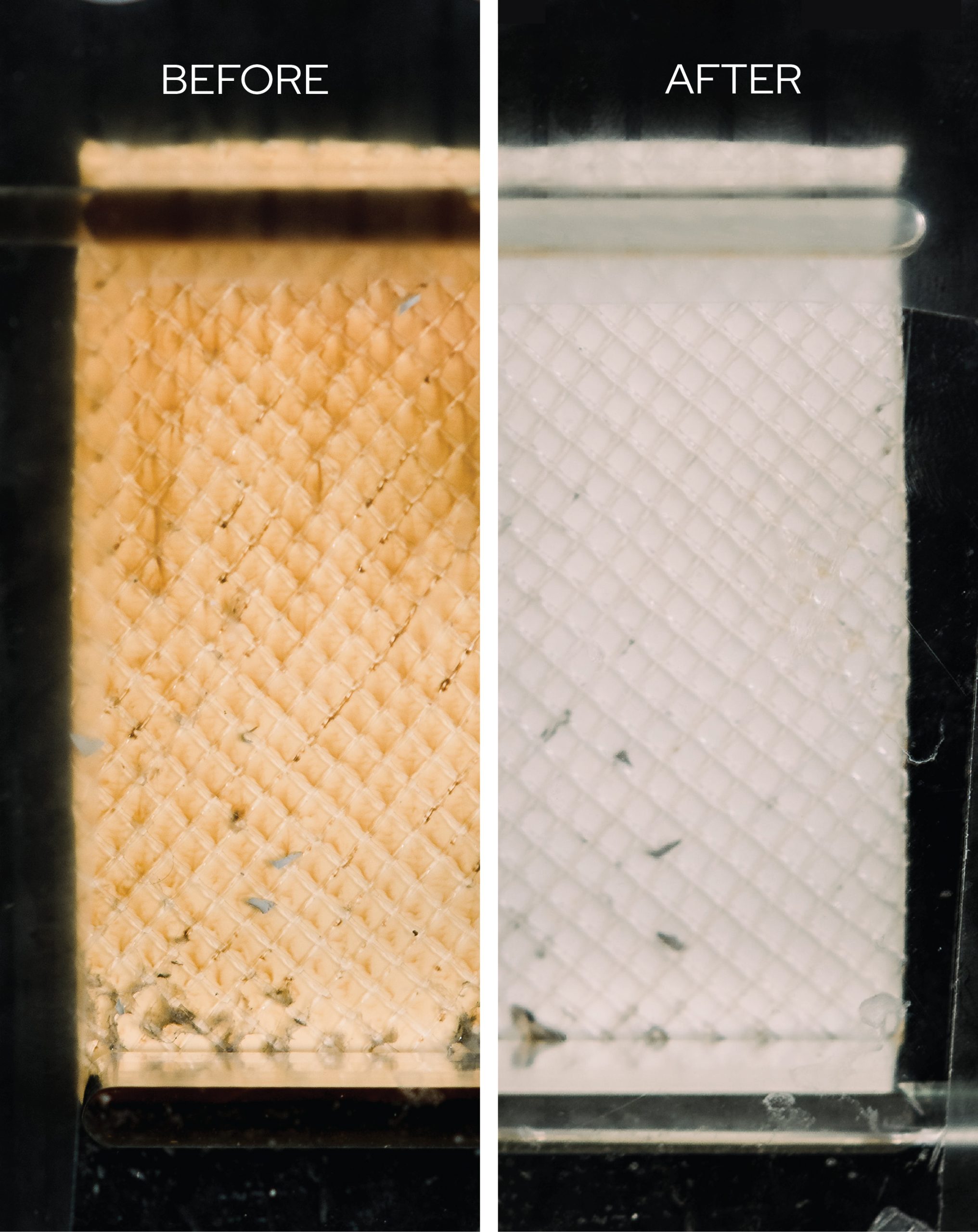

Our membranes are highly cleanable, often restoring over 80% of performance with short water flushes and up to 99% with a brief chemical clean-in-place process. Additionally, our Superfiltration Membrane Systems are chlorine tolerant, offering a swift and economical cleaning solution.

Advanced Superfiltration Technology for Fouling Resistance

- Introducing our innovative Superfiltration Membrane Systems, equipped with patented technology to resist fouling by fats, oils, and proteins.

- Achieve superior water clarity ready for Reverse Osmosis (RO) as our membranes remove over 99% of molecules larger than 1 kDa.

- Our compact and cost-effective spiral wound elements fit seamlessly into standard membrane housings and system components.

- Enjoy hassle-free maintenance with easy cleaning using caustic and bleach, a standout feature as most membranes in this class lack bleach tolerance.

- Optimize your process with the small organics present in our Superfiltration Membrane Systems’ concentrate, ideal for recycling to digesters.

- With an expected lifespan of 2-3 years, our membranes offer durability and reliability for long-term use.

Unlocking Superior Filtration with Digested Organic’s Superfiltration Membrane Systems

Digested Organic’s Superfiltration Membrane Systems revolutionize liquid filtration by effectively removing contaminants and impurities from various streams. These advanced membrane systems are designed to deliver high-performance filtration, ensuring the separation of valuable substances such as proteins and oils while efficiently removing organics and impurities. Whether it’s treating landfill leachate or optimizing anaerobic digestate treatment processes, Digested Organic’s Superfiltration Membrane Systems provide reliable solutions for industries seeking superior filtration performance.

Applications of Superfiltration Membrane Systems

- Harness the power of our Superfiltration Membrane Systems for the separation of valuable protein and oil products from process streams.

- Ensure the removal of organics and other impurities before Reverse Osmosis with our advanced membrane technology.

- Experience efficient treatment of landfill leachate, effectively removing color and organics, thanks to our Superfiltration Membrane Systems.

- Optimize the treatment of anaerobic digestate, particularly effective post pre-filtration, with our advanced membrane solutions.

FAQs: Superfiltration Membrane Systems

What are Superfiltration Membrane Systems?

Superfiltration Membrane Systems are advanced filtration systems designed to separate and remove contaminants and impurities from liquid streams. They utilize specialized membranes to achieve high-performance filtration, ensuring the retention of valuable substances while effectively removing unwanted particles and molecules.

How do Superfiltration Membrane Systems work?

Superfiltration Membrane Systems work by employing semi-permeable membranes that allow certain particles to pass through while blocking others. These membranes are engineered to have specific pore sizes, allowing them to selectively remove contaminants based on their molecular size. As the liquid passes through the membrane, impurities are trapped, resulting in purified filtrate.

What are the key benefits of using Superfiltration Membrane Systems?

Some key benefits of Superfiltration Membrane Systems include superior filtration efficiency, the retention of valuable substances, such as proteins and oils, efficient removal of contaminants and impurities, and versatility in applications ranging from wastewater treatment to food and beverage processing.

What industries can benefit from Superfiltration Membrane Systems?

Superfiltration Membrane Systems find applications in various industries, including wastewater treatment, food and beverage processing, pharmaceutical manufacturing, chemical processing, and biotechnology. They are particularly useful in processes requiring precise separation and purification of liquids.