SPIRAL BRUSH FILTER

AUTOMATIC SELF-CLEANING FILTER

HOW

SPIRAL BRUSH FILTRATION

WORKS

HOW

SPIRAL BRUSH FILTRATION

WORKS

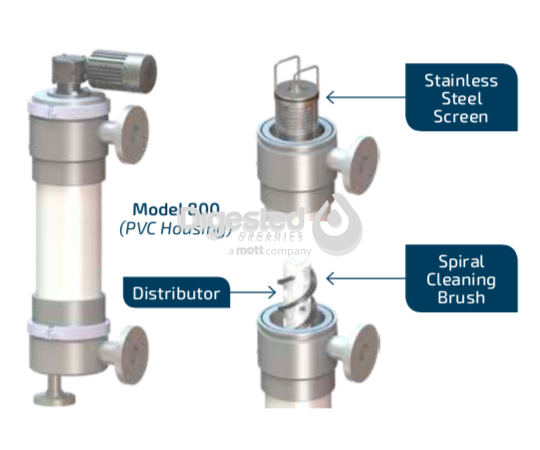

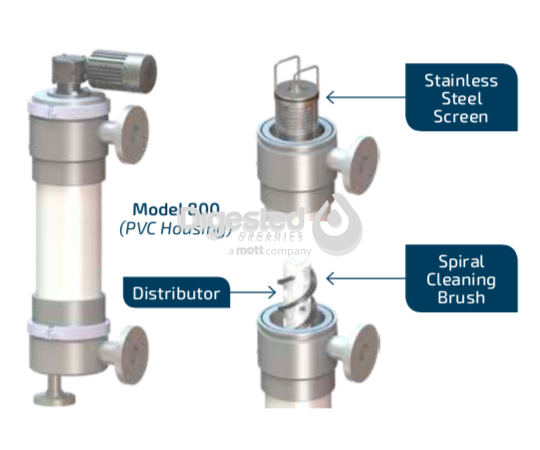

Model 1000

(Stainless Steel Housing)

Model 1000

(Stainless Steel Housing)

Benefits

Automatically purges when solids accumulate

Continuously filters – no disruption in flow for purging or backwashing

Concentrates solids for more cost-effective management

Small footprint and energy efficient

Modular and scalable to any flow

Low pressure drop and high filtrate recovery

Benefits

Automatically purges when solids accumulate

Continuously filters – no disruption in flow for purging or backwashing

Concentrates solids for more cost-effective management

Small footprint and energy efficient

Modular and scalable to any flow

Low pressure drop and high filtrate recovery

Typical Throughput* (GPM)

SCREEN SIZE

(MICRONS)

MODEL

800

MODEL

1000

15

20

100

20

30

133

25

25

165

50

50

250

*For water with TSS up to 1,000 mg/L. At higher loadings, throughput will be reduced.

DO MetricsTM

Our online dashboard for remote monitoring and data reporting.

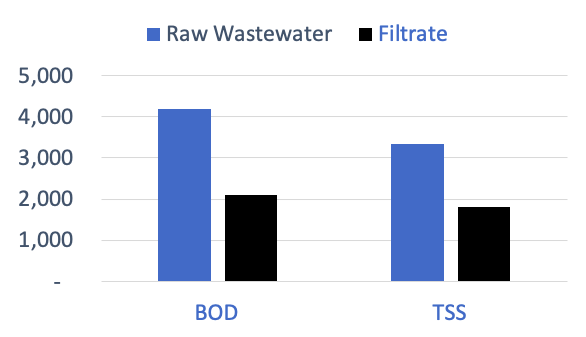

Case Study:

Potato Chip Manufacturer

Demonstration Unit Onsite

Purged Solids (sold as animal feed)

Significant surcharge savings!

51% BOD removal

47% TSS removal

Contact US:

Digested Organics LLC

23745 Research Dr

Farmington Hills, MI 48335

Toll-Free: 844-934-4378

Local: 734-545-8016

[email protected]

Work with us to Reclaim Your WasteTM

EXPLORING Filtration

Call to learn how a Spiral Brush Filter can help your facility. We will assess your current situation and recommend the best solution for you.

TESTING Filtration

We will pilot test your material at our facility in Michigan or bring our equipment onsite, providing you with a thorough report and proposal for a full-scale system.

IMPLEMENTING Filtration

We deliver, install, and commission your new filtration system and teach employees how it works, ensuring it meets your expectations.

MAINTAINING Filtration

Our filtration equipment will become an integral part of your facility and allows you to streamline and expand your operations while reducing wastewater treatment costs.

© 2019 Digested Organics