From the CEO's Desk

This year is off to a great start and we are enthusiastic about the roll-out of several systems that we are shipping this month. We have units destined for food and beverage manufacturing plants, farms filtering manure, and a large Kentucky distillery, among other projects. We have grown the fabrication/assembly and engineering team and moved to new headquarters in the Detroit area. We are more passionate than ever about finding new ways to help customers Reclaim Waste. Through our advanced filtration solutions, you can reduce wastewater disposal costs, reclaim clean water, and even create unique products. We look forward to meeting you at the North American Manure Expo, WEFTEC, and other shows this year.

Wilderness Trail Distillery to Install Stillage Filtration System

Digested Organics is partnering with the award-winning Wilderness Trail Distillery to take on the challenge of managing stillage disposal. Working with owners Shane Baker and Pat Heist, we engineered a customized filtration solution comprising our unique stainless steel Ultrafiltration (UF) and Two-Step Reverse Osmosis (TSRO) solutions. The result? We can process whole or thin stillage into clean, reusable water and concentrated co-products.

How Does It Work? Whole stillage will be processed in the UF to recover about 65% as ultra-thin stillage and 35% as a high solid concentrate. The ultra-thin stillage is ideal for use as backset while the high-solid concentrate is valuable as an animal feed and is easily pumpable for transportation in tanker trucks. The ultra-thin stillage that isn’t used as backset will be further purified to produce clean water and a second concentrate product using the TSRO system.

What Are the Benefits? Reduced truck trips for stillage transport, increased production, and reduced freshwater consumption. To learn more, check out our Stillage Filtration System Overview.

Want a Tour? Tours of the project at Wilderness Trail Distillery will be available starting in June by request.

Biodiesel Facility Evaluating Ultrafiltration of Oily Wastewater

After water washing raw oil and centrifuging, a commercial biodiesel facility was struggling with high surcharges for wastewater rich in FOG, BOD, and TSS. They are currently evaluating our stainless steel UF technology with an onsite 6-month rental. Chief Engineer Ian Charles, pictured here, wrapped up installation in February and the unit has been running well since. The permeate is free of FOG and TSS and shows a 50-60% reduction in COD. The unit has been able to run long stretches between cleaning and is fully automated, requiring minimal operator attention.

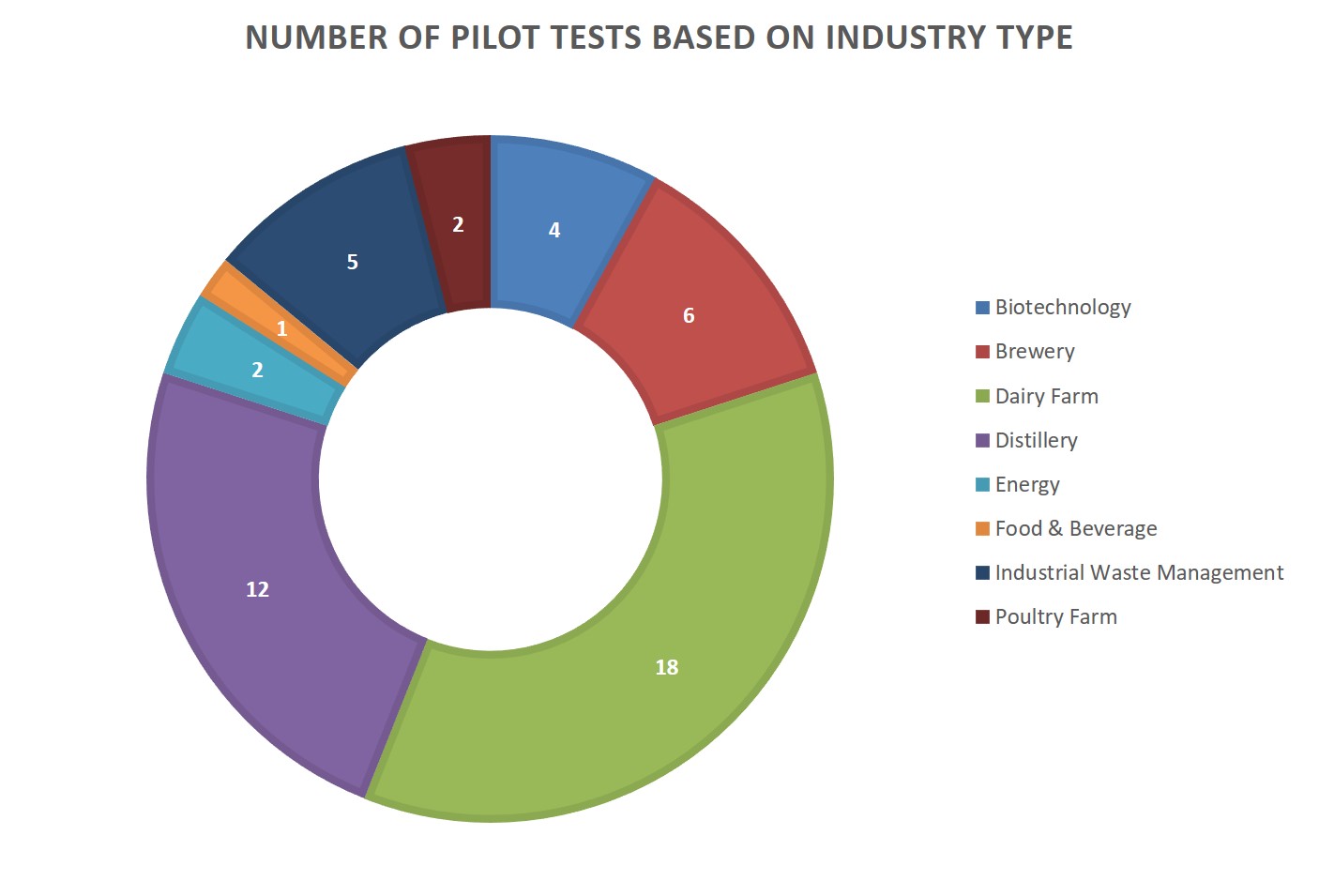

Fifty Pilot Tests of Diverse Materials Since January

Our R&D Engineer Sam Bagchi has been busy in the lab running a wide variety of materials. From brewery wastewater to milk to polymers destined to become diapers, we are always looking for new and interesting materials to try filtering. Here’s a snap shot of what we’ve been testing in the lab since January.