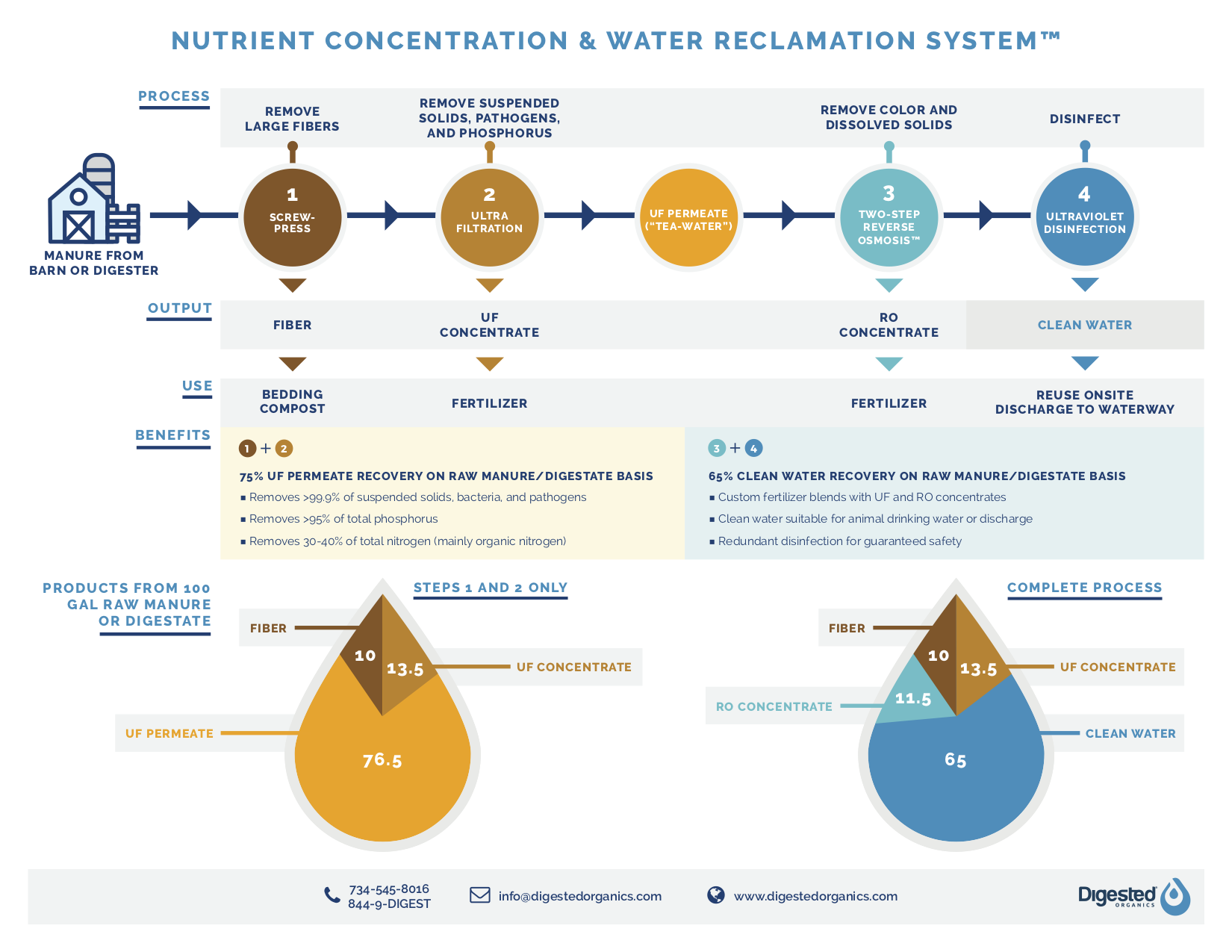

BENEFITS & IMPACTS

By combining our exclusive solutions, such as the Spiral Brush Screen, stainless steel Ultrafiltration (UF) and Forward Osmosis™ (FO), we can deploy totally integrated solutions for nutrient concentration and water reclamation.

The Nutrient Concentration & Water Reclamation (NCWR)™ System can process raw wastewaters, manures, and digestates, and separate the flow into clean, reusable water–ideal for facility re-use or discharge–and concentrated liquid fertilizer. With most materials, we can recover more than 70% of the total volume as clean water while concentrating the nutrients about 3-5x.

Reduced disposal costs

Reduced freshwater consumption

Reduces environmental impact of wastewaters

Opportunity for facility expansion

Generates value-added products

HOW IT WORKS

Step 1: Coarse Solids Removal

Typically we employ our Spiral Brush Screen, vibratory screen, or screw-presses to remove large solids from wastewaters prior to treating them with ultrafiltration. Some wastewaters don’t require ultrafiltration after coarse solids removal and can go directly into the FO.

Step 2: Ultrafiltration

For high-solids wastewaters like manure or digestate, we process it using our stainless steel ultrafiltration modules. Our unique module geometry and stainless steel construction ensures high filtration rates, easy cleaning, and long filter life (10+ years!). The UF modules contain porous metal tubes, allowing them to capture of all the suspended solids, bacteria, and even some larger dissolved compounds. This process results in a thick concentrate stream and a clarified product we call UF Permeate (or sometimes called “tea-water”).

Step 3: Forward Osmosis

The liquid “tea-water” or UF permeate is then pumped through our Forward Osmosis (FO) process. Instead of exposing traditional RO membranes directly to the UF permeate, which typically still contains a large amount of dissolved organic matter that leads to fouling and poor performance, we use Forward Osmosis to remove the water. This liberated water is then recovered using Reverse Osmosis (RO), resulting in a very clean final effluent that is suitable for drinking water for animals, reuse onsite as washdown water, for irrigation, or river discharge. This two-step process results in an overall lower cost of treatment, higher amount of water recovery, and less energy consumed.

Step 4: UV Disinfection

The final step when water is reused is a redundant disinfection using ultraviolet (UV) light. Since nearly all organisms are considered to be removed by the UF and FO, this UV disinfection step is simply an extra precaution. Multiple safeguards ensure that our system will not release water that is not properly treated.

Competitive Advantages

NO polymers or flocculants

Fully automated for continuous operation

Energy efficient

Compact and space efficient

Comprehensive Service Plan

We have created a Comprehensive Service Plan (CSP) to cover all the associated operating costs of the NCWR system with the exception of electricity. With the CSP, you know upfront what it will cost you to process your wastewater. In every case we’ve looked at to date, our system can substantially reduce a facility’s cost for wastewater management. We also remotely monitor the performance of your system and make adjustments as needed, as well as perform quarterly visits for inspection and tuning, provide all required consumables, and ensure your 100% satisfaction.

Case Studies

Stillage Filtration & Treatment (Wilderness Trail)

Have manure, digestate, leachate, or another wastewater?

Let us bring our demo skids to your facility for an evaluation of our technology. We’ll collect the data we need to accurately size a system for your full flow and you’ll get to the system make clean water and concentrated fertilizer.

Reference Articles

Fresh From The Blog