Leading the Way in Water Treatment with Microfiltration and Ultrafiltration Systems

Microfiltration and Ultrafiltration systems from Digested Organics, incorporating advanced sintered alloy filter element technology, are designed to tackle the most challenging wastewater treatment applications. These systems efficiently separate solids from liquids, offering a sustainable solution for industries looking to improve their waste management processes. With durable construction and high-efficiency filtration capabilities (media grades 0.5, 0.25, and 0.025), these systems stand out as robust solutions for achieving superior water purity.

Key Features

The Microfiltration / Ultrafiltration system offers a suite of key benefits tailored to meet the rigorous demands of various industries:

- Porous stainless-steel tubular membranes (3/4” ID) with internal titanium dioxide coating

- Welded and bolted construction in ASME code-stamped pressure vessel; 5′, 10’ and 20’ lengths available in any diameter

- Membranes last 10-15 years in challenging applications with little downtime, maintenance, or repair

- Simple, robust system with no internal moving parts and efficient externally mounted pump

- Flexible and Tunable: Can operate in batch-mode or continuously and be mounted horizontally or vertically

- Proudly manufactured in the USA

How our Microfiltration / Ultrafiltration System works

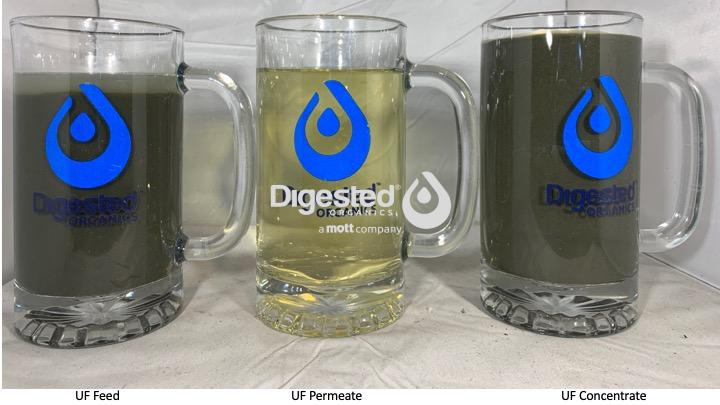

To understand the efficiency of our Microfiltration / Ultrafiltration system featuring advanced ultrafiltration tube technology, let’s take a look at the three-step filtration process:

- The feed pump introduces the material into the ultrafiltration (UF) modules.

- Within these modules, the material is circulated through the ultrafiltration tubes by recirculation pumps, with the option to arrange multiple modules in series for expanded filtration area.

- The filtrate permeates the tube walls into the module shell, exiting at the top, while the concentrated material is discharged through a flow control valve, ensuring efficient separation and purification.

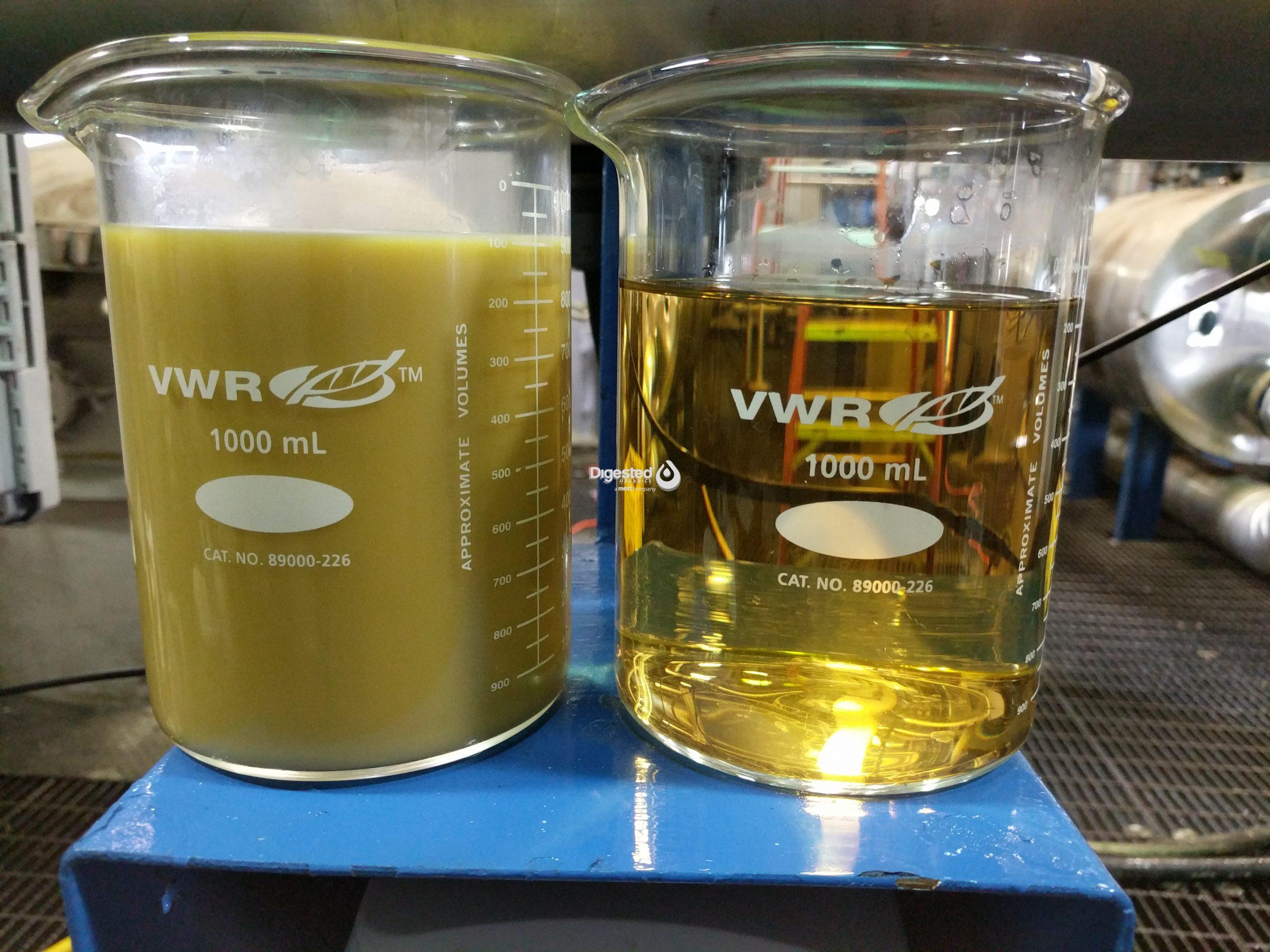

Ultrafiltration Pilot Testing

If you’re dealing with manure, digestate, leachate, or other wastewater types, consider our Microfiltration / Ultrafiltration system for a comprehensive evaluation.

We can bring demo skids directly to your site or analyze your material at our facility to tailor an ultrafiltration system to your needs.

This includes collecting essential data, along with providing analytical results, images, and samples of both the permeate and concentrate.

Contact us to arrange a trial and discover how our ultrafiltration solutions can benefit your operations.

Leading the Way in Water Treatment with Microfiltration / Ultrafiltration Systems

The Microfiltration / Ultrafiltration system from Digested Organics, incorporating advanced ultrafiltration tube technology, is designed to tackle the most challenging wastewater treatment applications. This system efficiently separates solids from liquids, offering a sustainable solution for industries looking to improve their waste management processes. With its durable construction and high-efficiency filtration capabilities, this system stands out as a robust solution for achieving superior water purity.

APPLICATIONS

Manure and digestate

Food waste digestate

Landfill and compost leachates

Sanitary food and beverage processing (including milk)

Food and beverage wastewater

Biodiesel and Oily Wastewaters

Case Studies

Raw Manure Treatment

Brewery Wastewater Treatment

Food & Beverage Wastewater Treatment

Food Waste Digestate Treatment

Ultrafiltration for Biotechnology Company

Stillage Filtration & Treatment (Wilderness Trail)

Learn more by downloading application-specific technical briefs:

Recent Ultrafiltration Systems Delivered

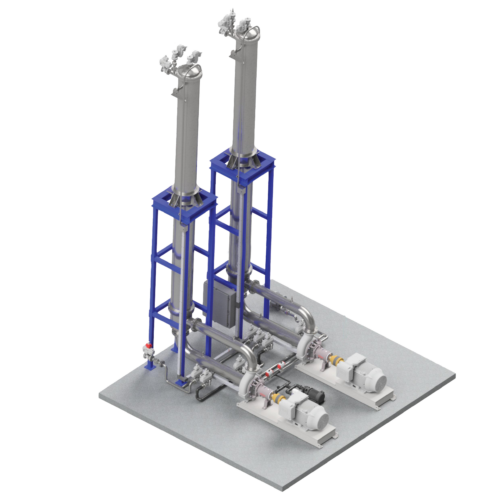

Model 400-4 Series

Four 4″ diameter x 5′ long elements containing 14 UF membrane tubes each

Total filtration area: 52.8 sq.ft.

Footprint: 10′ x 4′

Application: Dairy Processing

Model 400-8 Series

Eight 4″ diameter x 5′ long elements containing 14 UF membrane tubes each

Total filtration area: 105.6 sq.ft.

Footprint: 10′ x 4′

Application: Manure Filtration

Model 1800-2 Series

Two 18″ diameter x 10′ long elements containing 278 UF membrane tubes each

Total filtration area: 1048 sq.ft.

Footprint: 15′ x 4′

Application: Manure Filtration

Model 2000-2 Series

Two 20″ diameter x 20′ long elements containing 346 UF membrane tubes each

Total filtration area: 2,608 sq.ft.

Footprint: 15′ x 18′

Application: Stillage Filtration

Model 2600-2

Two 26″ diameter x 20′ long elements containing 606 UF membrane tubes each

Total filtration area: 4,570 sq.ft.

Footprint: 18′ x 20′

Application: Food Waste Digestate

FAQs: Microfiltration / Ultrafiltration

What is an ultrafiltration tube?

An ultrafiltration tube is a component of water treatment systems that uses a semi-permeable membrane to separate particles and substances from water, enhancing purification and filtration processes.

How does a Microfiltration / Ultrafiltration system work?

An ultrafiltration system operates by pushing water through ultrafiltration tubes within a durable stainless steel framework, effectively removing contaminants and ensuring high-quality filtration for various applications.

What are the benefits of using an ultrafiltration system?

The primary benefits include long-term durability, resistance to corrosion, high efficiency in filtering diverse contaminants, and the ability to handle high volumes of water, making it ideal for industrial and commercial water treatment.

Can the ultrafiltration tube technology handle industrial wastewater?

Yes, ultrafiltration tube technology is designed to efficiently process and purify industrial wastewater, removing solids, bacteria, and other particles to meet environmental standards and reuse criteria.