Key Features

Porous stainless-steel tubular membranes (3/4” ID) with internal titanium dioxide coating

Welded and bolted construction in ASME code-stamped pressure vessel; 5′, 10’ and 20’ lengths available in any diameter

Membranes last 10-15 years in challenging applications with little downtime, maintenance, or repair

Simple, robust system with no internal moving parts and efficient externally mounted pump

Flexible and Tunable: Can operate in batch-mode or continuously and be mounted horizontally or vertically

Proudly manufactured in the USA

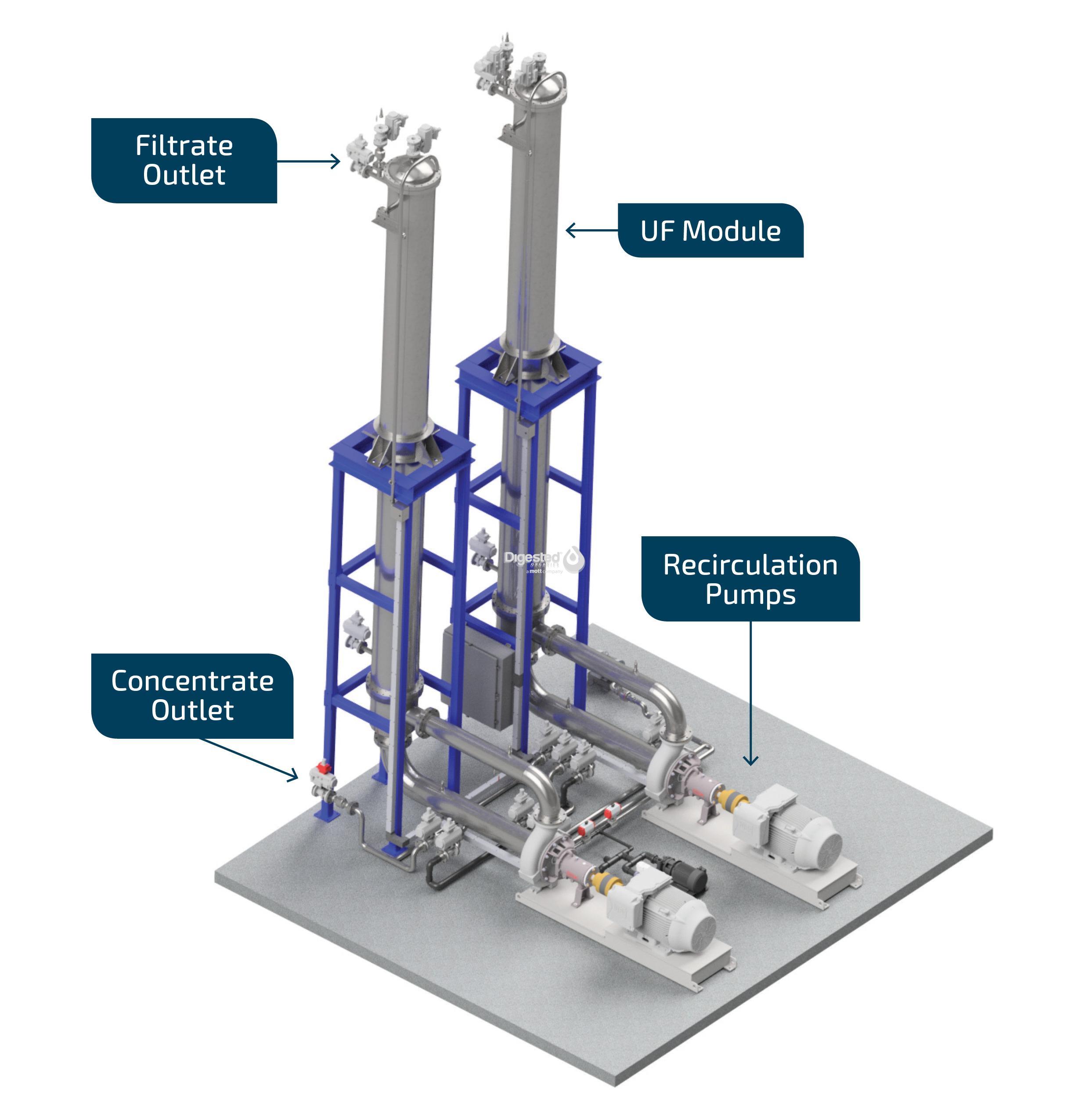

How it Works

1. Material to be filtered is pumped into the UF modules by the Feed Pump.

2. The material is recirculated through the tubes in the UF modules by the Recirculation Pumps. Multiple modules can typically arranged in series to provide the required filtration area.

3. Filtrate passes through the wall of the tubes and fills the module shell, exiting at the top of the module. The thickened concentrate exits through a flow control valve.,

Tube

Tube Module

APPLICATIONS

Manure and digestate

Food waste digestate

Landfill and compost leachates

Sanitary food and beverage processing (including milk)

Food and beverage wastewater

Biodiesel and Oily Wastewaters

Recent Ultrafiltration Systems Delivered

Model 400-4 Series

Four 4″ diameter x 5′ long elements containing 14 UF membrane tubes each

Total filtration area: 52.8 sq.ft.

Footprint: 10′ x 4′

Application: Dairy Processing

Model 400-8 Series

Eight 4″ diameter x 5′ long elements containing 14 UF membrane tubes each

Total filtration area: 105.6 sq.ft.

Footprint: 10′ x 4′

Application: Manure Filtration

Model 1800-2 Series

Two 18″ diameter x 10′ long elements containing 278 UF membrane tubes each

Total filtration area: 1048 sq.ft.

Footprint: 15′ x 4′

Application: Manure Filtration

Model 2000-2 Series

Two 20″ diameter x 20′ long elements containing 346 UF membrane tubes each

Total filtration area: 2,608 sq.ft.

Footprint: 15′ x 18′

Application: Stillage Filtration

Model 2600-2

Two 26″ diameter x 20′ long elements containing 606 UF membrane tubes each

Total filtration area: 4,570 sq.ft.

Footprint: 18′ x 20′

Application: Food Waste Digestate

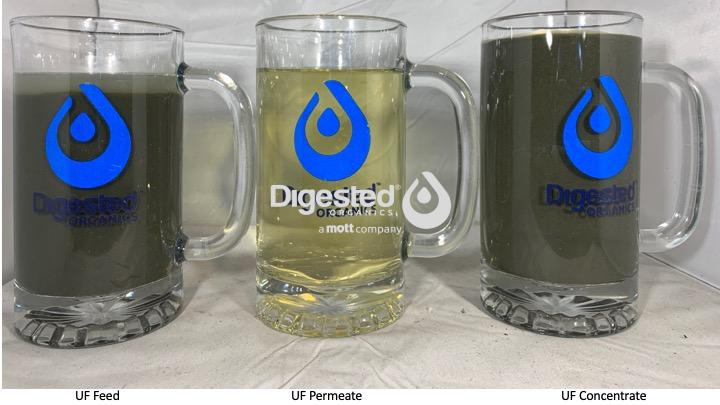

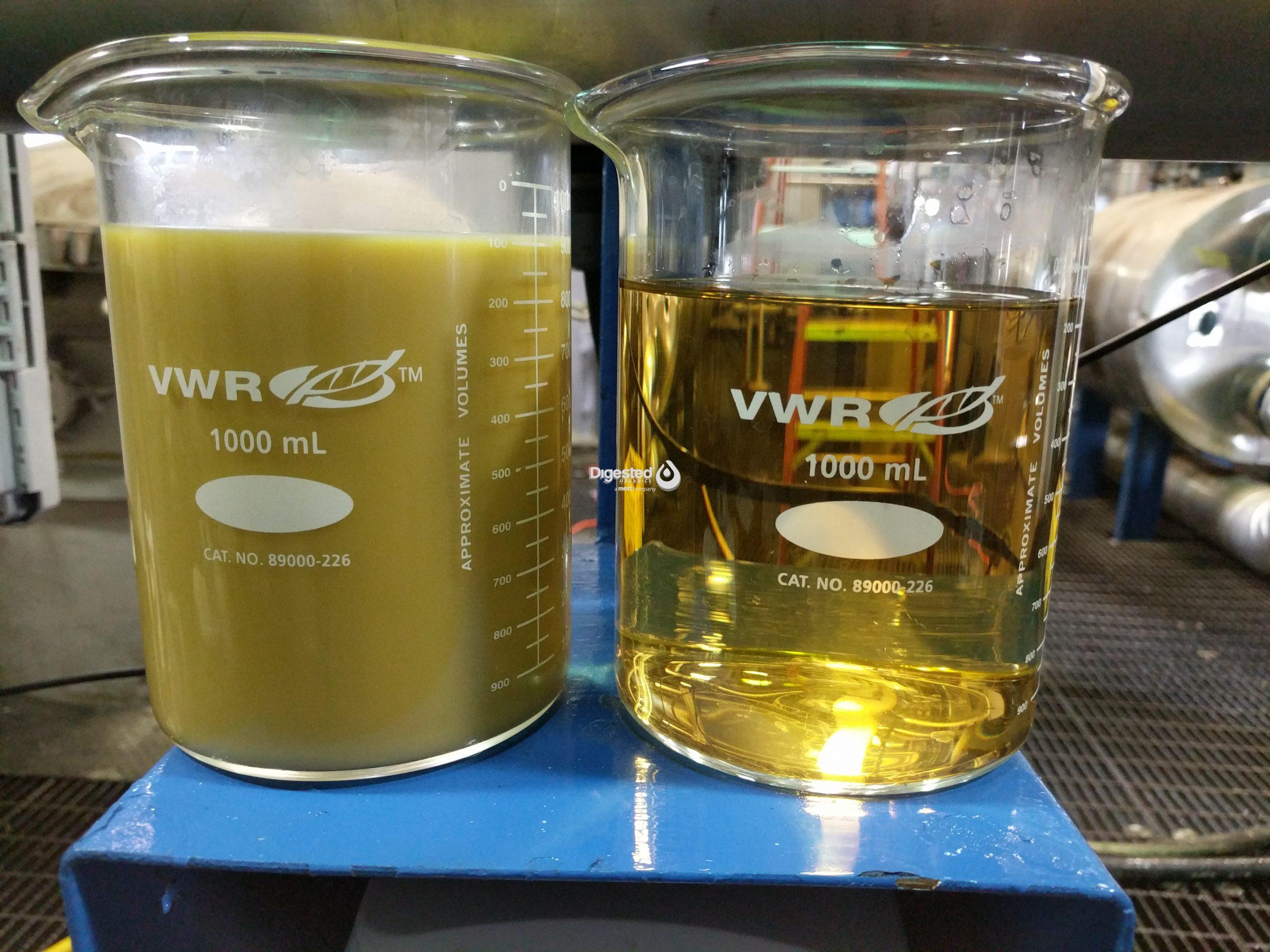

ULTRAFILTRATION PILOT TESTING

Have manure, digestate, leachate, or another wastewater?

Let us bring our demo skids to your facility or ship your material to us for a detailed evaluation of our technology. We’ll collect the data we need to accurately size a system for your full flow along with analytical data, pictures, and samples of the Ultrafiltration permeate and Ultrafiltration concentrate.

Please give us a call to schedule your trial today!