FOULING-RESISTANT SOLUTION FOR WATER

TWO-STEP REVERSE OSMOSIS TM

FOULING-RESISTANT SOLUTION FOR WATER

RECLAMATION AND NUTRIENT CONCENTRATION

HOW

TWO-STEP

REVERSE OSMOSIS

WORKS

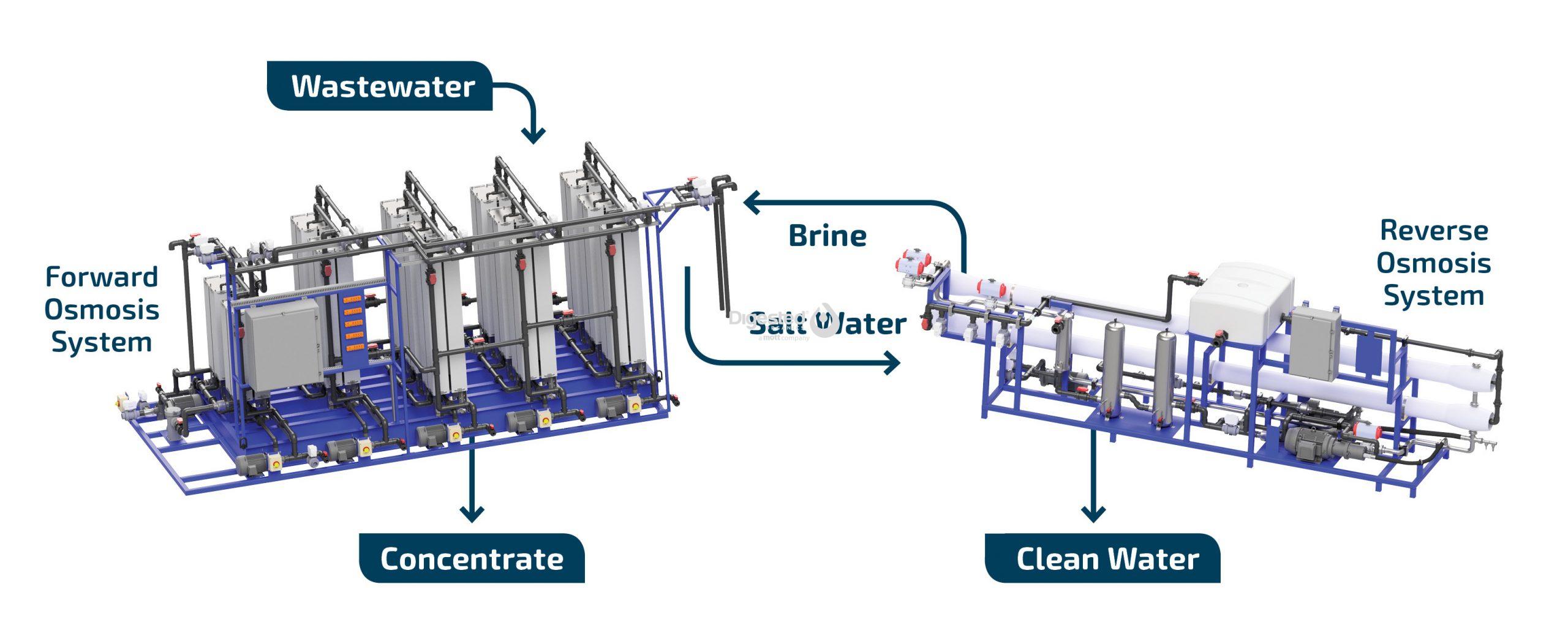

The Two-Step Reverse Osmosis System is comprised of a “Stack” of proprietary Forward Osmosis (FO) membranes that work together with traditional Reverse Osmosis (RO) membranes to concentrate wastewater and extract clean water.

HOW

TWO-STEP

REVERSE OSMOSIS

WORKS

The Two-Step Reverse Osmosis System is comprised of a “Stack” of proprietary Forward Osmosis (FO) membranes that work together with traditional Reverse Osmosis (RO) membranes to concentrate wastewater and extract clean water.

Technology Highlights

ANTI-FOULING, HIGH-FLUX MEMBRANE

Our FO membrane chemistry reduces fouling while maintaining high flux rates. It is also easy to clean.

DESIGNED TO LAST

We build systems with stainless steel pumps and hardware that’s designed to stand up to your toughest wastewater.

MINIMAL PRE-FILTRATION

Our open-channel FO membranes can handle wastewater with suspended solids and dissolved organic matter.

FLEXIBLE & TUNABLE

Our systems are highly tunable to handle variations in wastewater composition and flow rates while maintaining high permeate recovery and efficiency.

HIGHLY AUTOMATED

Our systems are fully automated so there is little operator attention required. They are also remotely accessible and we provide data logging solutions through our online DO Metrics platform.

Brewery Wastewater

Ultrafiltered stillage

Benefits:

The FO Stack can handle high solids wastewater that is rich in organic matter with minimal pre-filtration.

The FO runs at low pressures and has an anti-fouling membrane chemistry, allowing long run times between cleaning.

Produces very clean water from dual-filtration (FO+RO)

Compact footprint and highly scalable design

Proudly manufactured in the USA

DO MetricsTM

Our online dashboard for remote monitoring and data reporting.

Ultrafiltered Manure

Food & Beverage Wastewater

Contact US:

Digested Organics LLC

23745 Research Dr

Farmington Hills, MI 48335

Toll-Free: 844-934-4378

Local: 734-545-8016

[email protected]

Work with us to Reclaim Your WasteTM

EXPLORING Filtration

Call to learn how a Spiral Brush Filter can help your facility. We will assess your current situation and recommend the best solution for you.

TESTING Filtration

We will pilot test your material at our facility in Michigan or bring our equipment onsite, providing you with a thorough report and proposal for a full-scale system.

IMPLEMENTING Filtration

We deliver, install, and commission your new filtration system and teach employees how it works, ensuring it meets your expectations.

MAINTAINING Filtration

Our filtration equipment will become an integral part of your facility and allows you to streamline and expand your operations while reducing wastewater treatment costs.

© 2019 Digested Organics