STAINLESS-STEEL TUBULAR FILTRATION FOR

ULTRAFILTRATION

STAINLESS-STEEL TUBULAR FILTRATION FOR

THE MOST DEMANDING APPLICATIONS

HOW

ULTRAFILTRATION

WORKS

Our stainless-steel ultrafiltration (UF) systems are the toughest on the market today. With a 3/4” internal diameter tubular membrane made of 316L stainless steel, our membranes are abrasion resistant, handle extremes in temperature and pH, and can produce very thick concentrates. If we can pump it, we can filter it!

HOW

ULTRAFILTRATION

WORKS

Our stainless-steel ultrafiltration (UF) systems are the toughest on the market today. With a 3/4” internal diameter tubular membrane made of 316L stainless steel, our membranes are abrasion resistant, handle extremes in temperature and pH, and can produce very thick concentrates. If we can pump it, we can filter it!

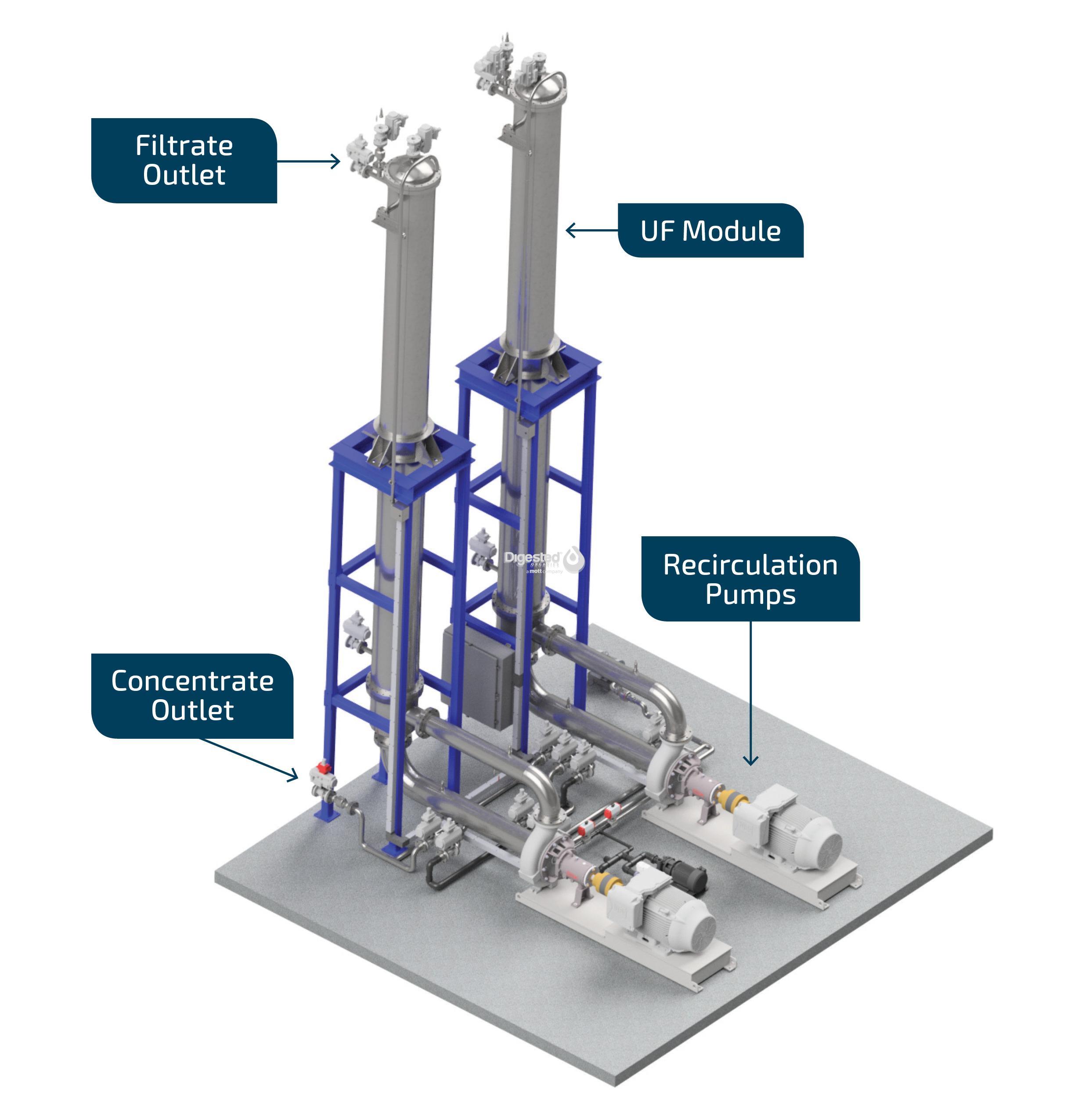

Technology Highlights

POROUS STAINLESS-STEEL

3/4” tubular membranes with internal titanium dioxide coating are abrasion, temperature, and chemically resistant.

WELDED & BOLTED CONSTRUCTION

ASME code-stamped pressure vessel available in any diameter to accommodate any size project.

DESIGNED TO LAST

Made to last 10-15 years in challenging applications with little downtime, maintenance or repair.

NO INTERNAL MOVING PARTS

Simple, robust system with no internal moving parts and efficient externally mounted pumps.

FLEXIBLE & TUNABLE

Can operate in batch-mode or continuously and be mounted horizontally or vertically.

Whole Stillage

Brewery Wastewater

Benefits:

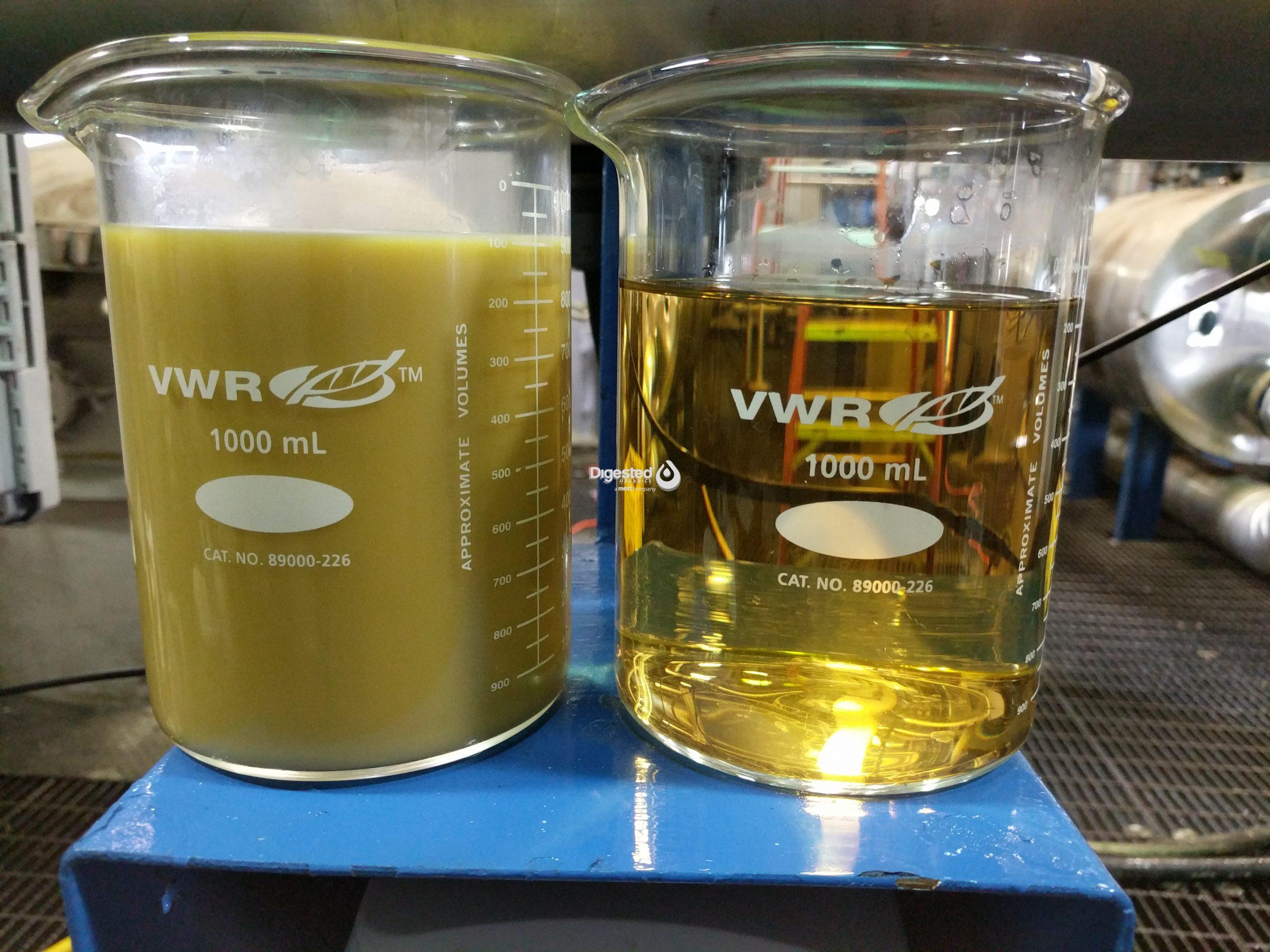

Create highly concentrated or perfectly clarified products with ease

Combine with aerobic or anaerobic systems to create a Membrane Bioreactor (MBR)

Fully automated systems require little operator attention

Handles high temperature, high solids, and oily liquids that most other filters cannot

Proudly manufactured in the USA

DO MetricsTM

Our online dashboard for remote monitoring and data reporting.

Oil Washing Wastewater

Food Waste Digestate

Contact US:

Digested Organics LLC

23745 Research Dr

Farmington Hills, MI 48335

Toll-Free: 844-934-4378

Local: 734-545-8016

[email protected]

Work with us to Reclaim Your WasteTM

EXPLORING Filtration

Call to learn how a Spiral Brush Filter can help your facility. We will assess your current situation and recommend the best solution for you.

TESTING Filtration

We will pilot test your material at our facility in Michigan or bring our equipment onsite, providing you with a thorough report and proposal for a full-scale system.

IMPLEMENTING Filtration

We deliver, install, and commission your new filtration system and teach employees how it works, ensuring it meets your expectations.

MAINTAINING Filtration

Our filtration equipment will become an integral part of your facility and allows you to streamline and expand your operations while reducing wastewater treatment costs.

© 2019 Digested Organics